Filters

Our Products

Chemical Process Equipment : Filters

Description

Nutsche Filters are constructed to perform a multitude of tasks including filtration, cake washing and thermal drying on a single unit. As such these are very sophisticated machines with tight process control on parameters such as pressure, temperature and pH. Nutsche Filters are well suited for handling flammable, toxic, corrosive and odor-noxious materials since they are autoclaved and designed for use in hazardous and ex-proof environments when extremely safe operation is required.

Nutsche Filters are available in almost any size with the larger machines for a slurry filling batch of 10 to 2000 ltrs. & a cake volume of 10 m3 to 2000 m3. Such filters have a filtration area of 5 m2 and are suitable for fast filtering slurries that produce readily 0.5 m thick cakes.

The Nutsche in its full configuration consists of four major components:

- The vessel

- The filter floor and cloth, woven mesh screen or sintered metal plate medium

- The re-slurry arms for cake washing and smoothing

- The cake discharge mechanism

All these components may be constructed from exotic materials of construction and heated to meet the process requirements.

Nutsche Filters are operating as part of a batch system hence the vessel’s volume is designed to accept an entire charge of slurry from the upstream equipment. Therefore, so that the idle time of the filter is kept to a minimum, sufficient holding volume is required for fast charging and emptying of the vessel. The vessels are generally designed for an operating pressure of 3 bars & full vacuum..

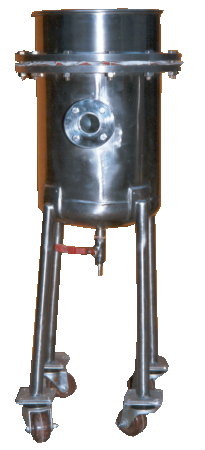

Sparkler Filter Press / Zero hold up

Description

Horizontal filter Press- Sparkler type consist of a Filter cartridge assembly with SS Filter plates, Support screens, Interlocking cups & SS tank with Pressure tight fitting System.

Salient Features

- All Contact Parts are in AISI S.S.304/ S.S.316L.

- Components are Argon Arc welded & polished to Mirror finish.

- SS Jacket can be provided for hot filtration.( Optional).

- Provides crystal clear filtration by filtering particles up-to 1 Micron Size.

- Scan enger arrangement to remove all the liquid.

- SS. Pump mounted on SS Trolley with ‘Nova ‘ make heavy duty thrust ball bearing castor wheels for easy movement.

- Provided with different types of pumps depending on the viscosity of liquid & output i.e Centrifugal Pump, Gear Pump, Lobe Pump, Pump etc.

- Provided with Bypass system, Safety Valve & Sample Collecting device.

- No contamination of internal surface of the shell.

Special Features

Horizontal Plate Sparkler Type Filter Press is constructed in such a manner that it prevents evaporation, oxidation, leakage & fumes escaping from product.

Plates are available in two sizes-Deep Plate for higher percentage of caking holding capacity & shallow Plate for er percentage of cake holding capacity.

Filter plate & Thickness of cake prevents the cake dropping as well as cracking, thus assuring better filtrate quality.

According to requirement filtration area & cake holding capacity can be increased or decreased.

Capacity : 8 PLATES,10 PLATES,12 PLATES,14PLATES,18PLATES.

Agitated Nutsche Filter

Nutsche Filtersnce